This course is designed for the HPLC beginners. The basics of HPLC is explained using simple words.

1. History of Chromatography

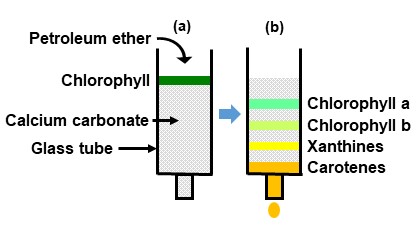

The history of chromatography dates back to the beginning of the 20th century. In 1903, a Russian scientist M. Tswett used a glass tube filled with chalk powder (calcium carbonate) and placed a pigment (chlorophyll) extracted from plant leaves (Figure 1(a)). Then, he poured petroleum ether to the tube. Which resulted in separating the pigment into different dyes (Figure 1(b)). This is the start of “chromatography”. Tswett used the term “chromatographische (Chromatography in German)” in the 1906 published German paper.

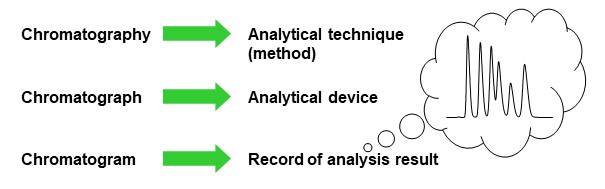

The word chromatography is thought to originate from the Greek words “chroma (khrōma, color)” and "graphos (gráphōs, record)”. According to IUPAC (Compendium of Chemical Terminology), a chromatography refers to a physical method of separation, a chromatograph as a noun refers to an assembly of apparatus for carrying out chromatographic separation, and a chromatogram refers to a graphical or other presentation of detector response.

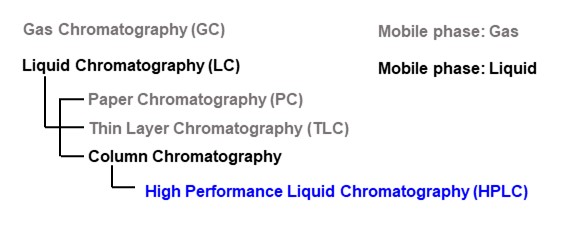

Chromatography is classified into several types; mainly based on which stationary phase (chalk powder in the Tswett’s method) and mobile phase (petroleum ether in the Tswett’s method) are used. The ones use gas for the mobile phase are called Gas Chromatography (GC), and the ones use liquid for the mobile phase are called Liquid Chromatography (LC). Among LC, several stationary phases are available and are categorized as different techniques.

2. What is an HPLC?

In the beginning of its use, the column chromatography required a considerable amount of analysis time. However, the development of high-pressure pumps in the 1970s dramatically shortened the analysis time. Then, this technique came to be called High Pressure Liquid Chromatography. Further improvements in packing materials and pumps led to the development of high-speed and high-performance analytical methods. Now, the name HPLC is commonly referred to as High Performance Liquid Chromatography.

In recent years, Ultra High Performance Liquid Chromatography (UHPLC), which provides even more sophisticated analysis with ultra-high-speed has also come into use.

3. Features of HPLC

The HPLC has four main features.

-

(1)Wide range of analysis targets

The minimum requirement for the sample to be analyzed by HPLC is that the analyte (analyte component) to be dissolved in a liquid. Non-volatile substances and thermally unstable compounds are difficult to analyze with GC, but they can also be analyzed by HPLC. -

(2)Quantitative analysis

HPLC offers a superior quantitative performance compared to other liquid chromatography methods. -

(3)Preparative separation

HPLC is eligible for preparative purposes. Since the analytes elute from the column along with the eluent, it is easy to separate and collect the target analyte by fractionating the elute. The collected fractions can be concentrated or dried if needed. -

(4)Availability of various separation modes (using different types of interactions)

HPLC supports various separation modes. There are hundreds of columns in the market with various separation modes. You can select a column with a separation mode suitable for the properties of your samples.

Because of mentioned features, HPLC is used in various situations, including research and development, product quality control, and environmental analysis at industries, universities, and research institutes.

4. HPLC System Components

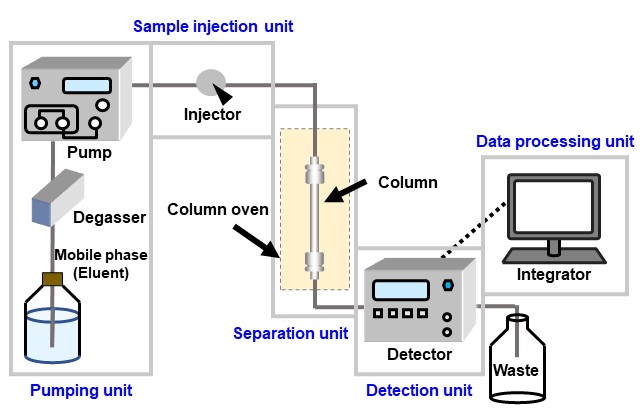

Figure 4 shows the basic components of an HPLC set-up. Explanations of each component follow below.

4-1. Pumping unit

Liquid pump

LC mobile phase is called eluent. A liquid pump is a device that delivers an eluent at a constant flow (flow rate). At the beginning of LC development, it was important for pumps to be able to use at high pressures. Old liquid pumps were reciprocating types, moved in piston like motions, which caused periodic pressure fluctuations (pulsation), and this resulted in wavy chromatograms. To reduce this pulsation influence, a device called a damper was installed in downstream of the liquid pump. Today's liquid pumps are mostly dual plunger type with reduced pulsations. Now, it is a standard requirement for the pumps to be used at high pressures and deliver eluents in stable flow and minimum pulsations.

Degasser

Water and organic solvents used as eluents are saturated with dissolved gases. When there are changes in temperature or pressure, the saturated dissolved gas may appear as air bubbles in the eluent. If the air bubbles occur in a flow path, it may cause pump failure, column performance deterioration, or produce noise during detection. Even if air bubbles do not appear, changes in the dissolved gas amount may cause baseline fluctuations. To avoid such troubles, it is important to remove (degas) the dissolved gas in the eluent. There are two methods for degassing the eluent: one is to degas the eluent in advance (offline degassing), and the other is to degas the eluent while it is being pumped (online degassing). The offline degassing methods include reduced pressure and ultrasonic waves. They are not only time-consuming, but also cause gas to gradually dissolve back into the eluent over time after it is set in the device. Particular care must be taken when using an aspirator reducing pressure method, as the eluent composition changes depending on the time spent on pressure reduction and which may affect the reproducibility of analysis. The online degassing methods include the use of helium gas purge and degasser. A helium gas purger sends helium gas into the eluent and replaces the dissolved gas with helium. Since the solubility of helium is lower than that of air, it makes it difficult for air to re-dissolve, but its running cost is high. Meanwhile, a degasser is installed at an upstream of liquid pump, and the eluent is degassed as it passes through the degasser. A special synthetic resin membrane tube (degassing membrane tube) runs inside the degasser. By creating a reduced pressure state around the degassing membrane tube, when the eluent flow through the degassing membrane tube, this mechanism allows only the dissolved gas to pass through the membrane and removes the gas to outside the tube. Each degasser has maximum flow rate limit. Exceeding this limit may result in insufficient degassing.

4-2. Sample injection unit

The sample solution is introduced into the HPLC flow path using an injector installed at downstream of the pump. Two types of injectors are available: manual injectors and auto-injectors (autosamplers).

Manual injector

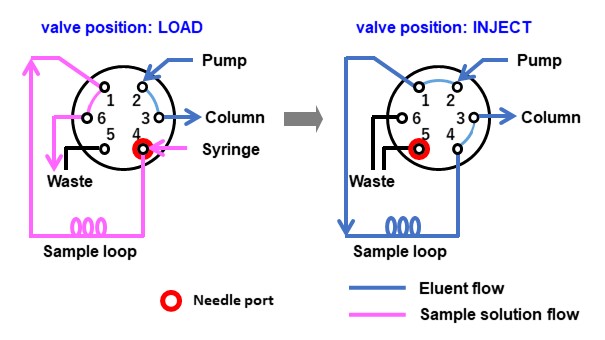

With a manual injector, set the valve position to INJECT and insert a micro syringe containing a sample solution. After switching the valve position to LOAD, press the micro syringe to inject the sample solution into the sample loop. By switching the valve position back to INJECT, the sample inside the sample loop is introduced into the HPLC flow path (Figure 5).

Autosampler

As the name tells, the autosampler automatically performs everything from aspirating the sample solution to injecting it into the HPLC flow path. Autosamplers are required to have high injection accuracy as well as suppressed carryover. In recent years, they have become more sophisticated with features such as cooling, dilution, and preprocessing of internal standards.

4-3. Separation unit

Column

A column is a cylindrical chromatography tube filled with a substance called a packing material. Sample components are separated as they pass through a column, so the column is the heart of the HPLC system. In the early days of chromatography, glass tubes were mainly used for chromatography tubes. However, with the required high pressure applied on the newer devices, materials having more pressure-resistant, such as stainless steel (SUS) and polyetheretherketone (PEEK) are mainly used now.

In addition, a variety of packing materials are available to support various separation modes. Columns used in HPLC will be explained more in Chapter 2. 8 HPLC Columns.

Column oven

A column oven is a device to keep a constant column temperature. Subtle changes in column temperature can affect the reproducibility and quantitative accuracy, and separation performance can vary greatly depending on column temperature. Therefore, it is important to maintain a column temperature at its optimal setting.

4-4. Detector unit

The detector detects the analyte eluted from the column and converts it into an electrical signal. Various principles are used for detection. There are highly versatile detectors that detect a wide range of analytes. Meanwhile, there are highly selective detectors that actively utilize the properties of analytes and detect only specific analytes. The detectors used in HPLC will be explained more in Chapter 5. Detector Unit.

4-5. Data processing unit

A data processing device (integrator) receives an electrical signal from the detector. Then, the device processes the signal and provide it as a chromatogram. In the past, recorders such as pen recorders were used, but now data processing devices are the mainstream. In addition to displaying chromatograms, the data processing device has functions to process peak and base line data, including the calculation of retention time, peak height, peak area, calibration curves etc.